animal feed production equipment

Product Description

https://www.pelletfeed.com/products.html

Feed mill equipment composition

The main components of the feed mill equipment in the feed pellet factory are a feed mill, feed mixer, feed pellet machine, feed pellet cooler and feed pellet packaging machine. The auxiliary equipment of the feed factory includes conveyors, control cabinets, storage bins, dust collectors, fire-fighting equipment, etc.

Basic operation of feed mill equipment

Basic feed mill equipment operations to produce animal or poultry feed pellets include raw material receiving, grinding, batching, mixing, pelleting, cooling, screening, packaging and warehousing.

Raw material receiving

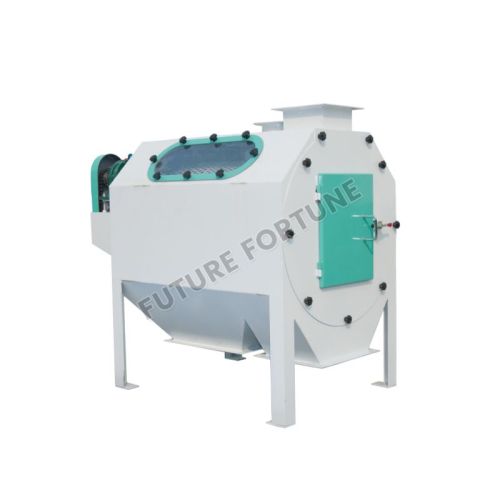

Feed mills are often equipped to receive grain and other raw materials for rail and truck shipments. Natural materials such as meat, fishmeal, fat, molasses and premixes are transported by truck, while grain and soybean meal are often fascinated by rail. Dry ingredients are received in bulk or in bags; liquid ingredients such as fat and molasses are pumped directly into storage tanks in the feed mill; elements such as bulk grain are conveyed by conveyors or bucket elevators to the cleaning machine to remove non-metallic foreign matter and metal impurities material, and then stored in the storage bin.

Grinding

Whole grains require a feed hammer mill before being mixed with other feed ingredients grind. Batching According to the feed formula, it is necessary to quantitatively weigh various feed materials with a batching scale. The quantity of various ingredients fed into the scale hopper is manually or automatically controlled by the central control panel.

Mix

Each batch of feed ingredients is mixed evenly in the feed mixer. The mixing time depends on the feed formula and the characteristics of the feed ingredients and feed mixer.

Pellet

Send the evenly mixed feed raw materials into the feed pellet machine. The granulation process involves several steps. First, the mixed raw materials are sent to the feeder of the pellet mill, and the feeder is used to control the rate at which the raw materials are conveyed to the feed pelletizing equipment; secondly, the dry blended materials and added steam are mixed together in the conditioner, A wet paste is formed, which is then fed by gravity or forced feeding system into the granulation chamber where the hot, moist paste is pushed through the granulator die and converted to particle size and shape.

Cooling, sieving

The hot feed pellets are gravity-fed into a pellet cooler, resulting in durable, hard pellets. The cooled granules flow directly into a screening machine to remove granular paste and fines.

Packaging and storage

The finished pellet feed is weighed, packed and sealed by the pellet packaging machine and then transported into the warehouse.